Preventing the adhesion of powdery, sticky or solidified substances is a demanding task. One solution for all does not exist, unfortunately, because each substance and surface show a different sliding behavior. Elevated temperature, high humidity or the presence of electrostatic charge have an additional negative impact, typically increasing the tackiness of the media.

Good and effective processes based on PTFE or other fluoroplastics are available. However, these materials basically lack a satisfactory wear resistance. The famous Teflon (® DuPont) frying pan is the best known and same time saddest example. The required stoving temperatures of over 250 °C (480 °F) additionally limit the retrofittability of these thermoplastic thin films into existing, problematic constructions.

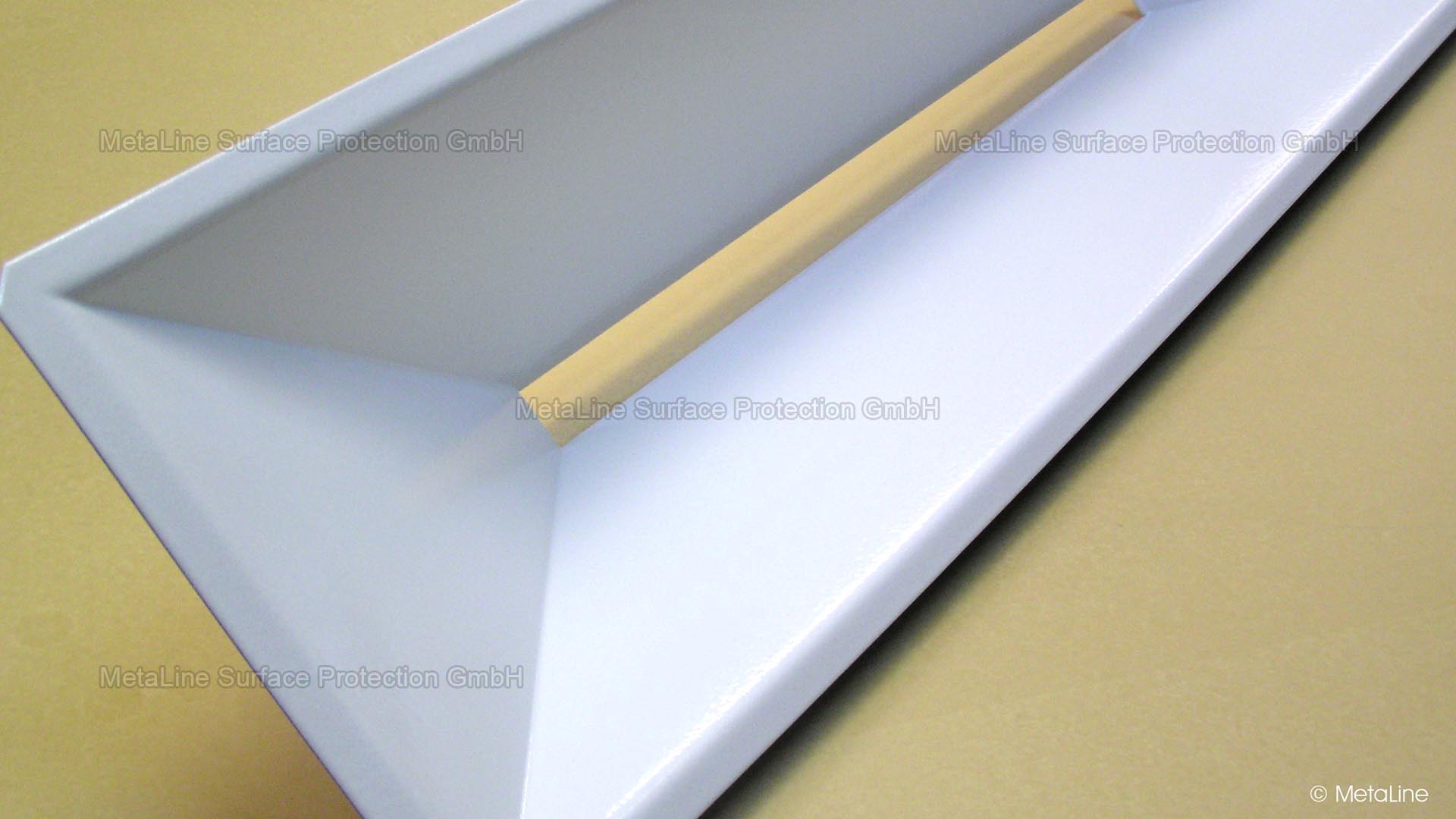

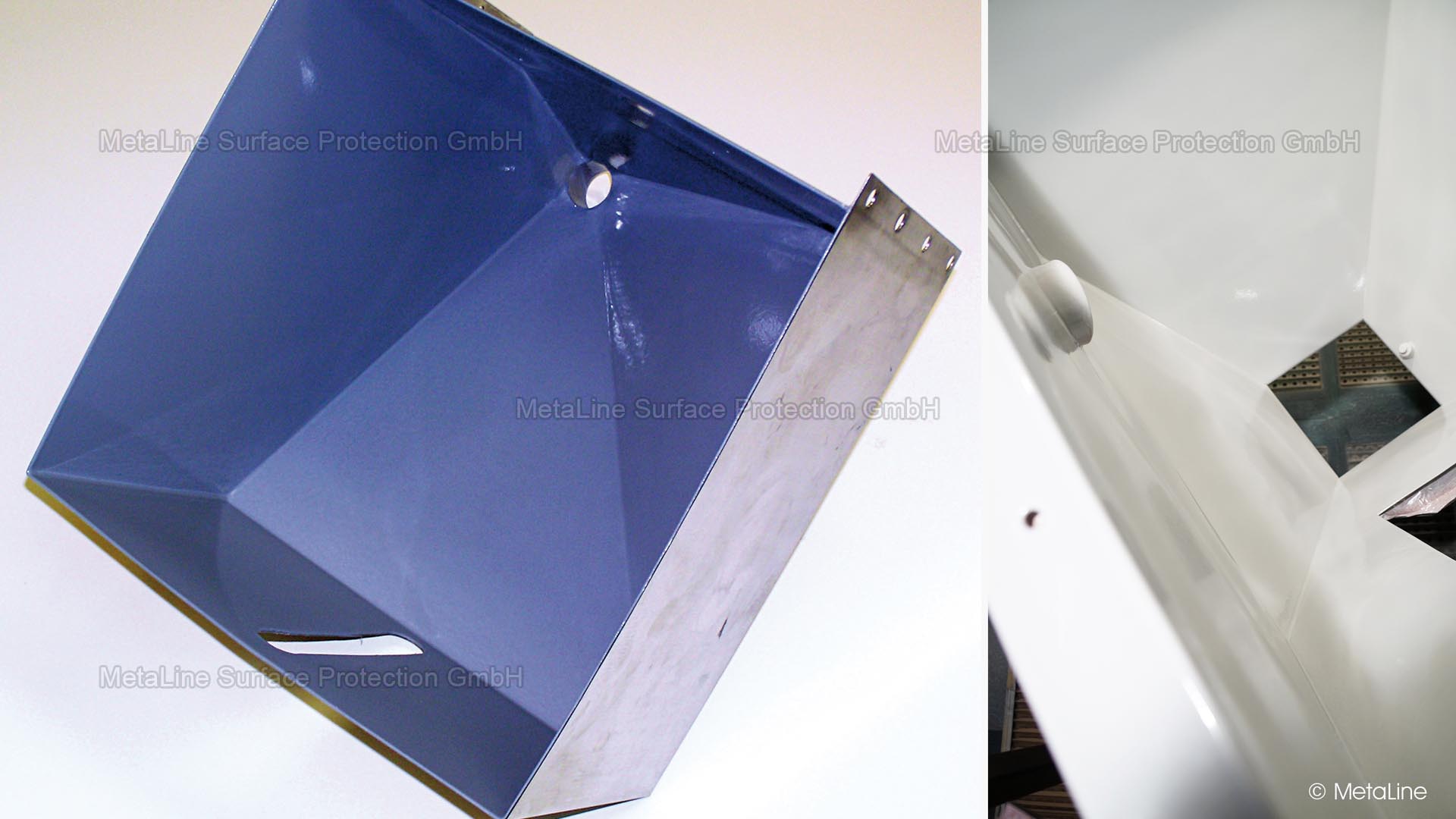

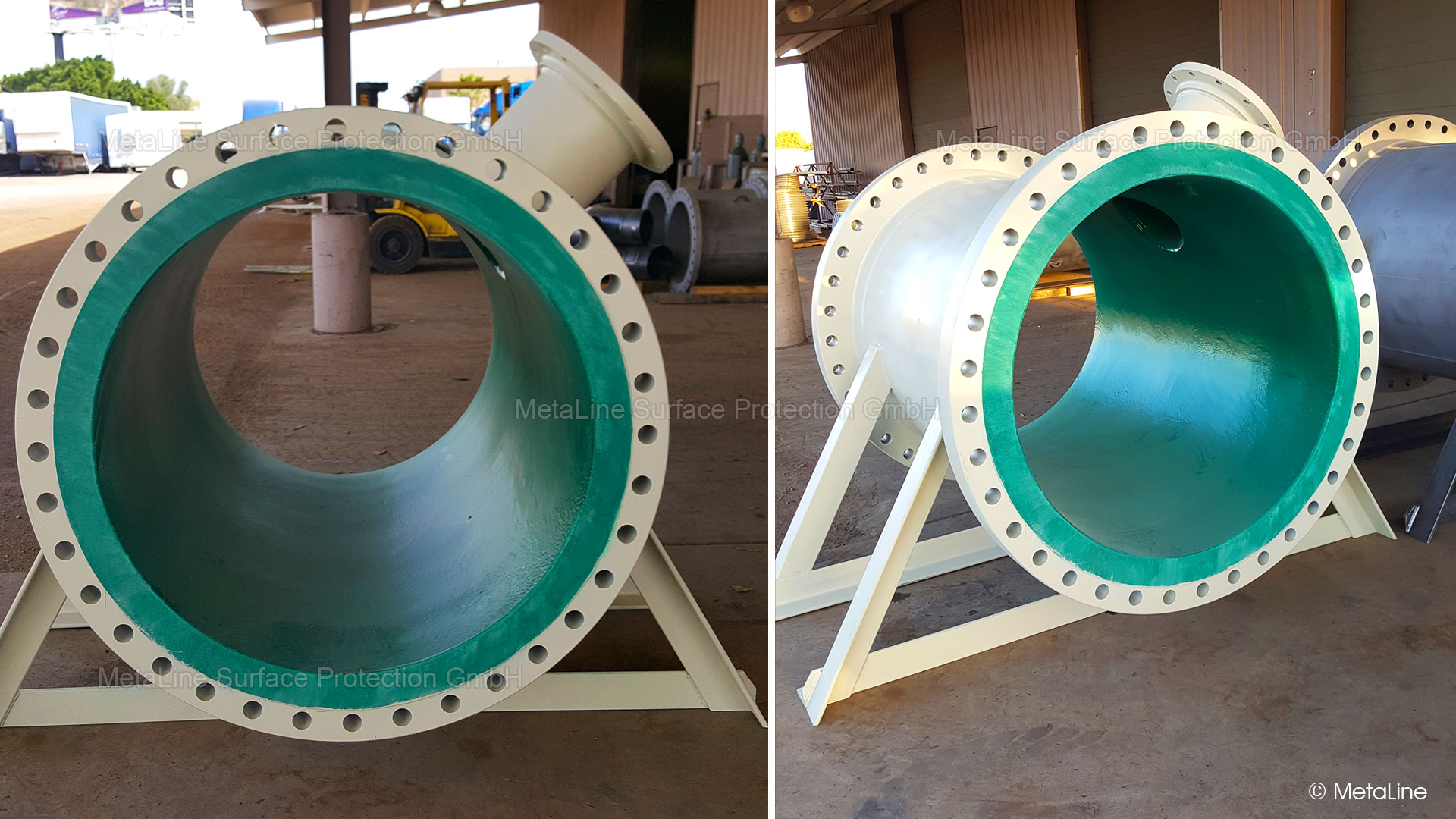

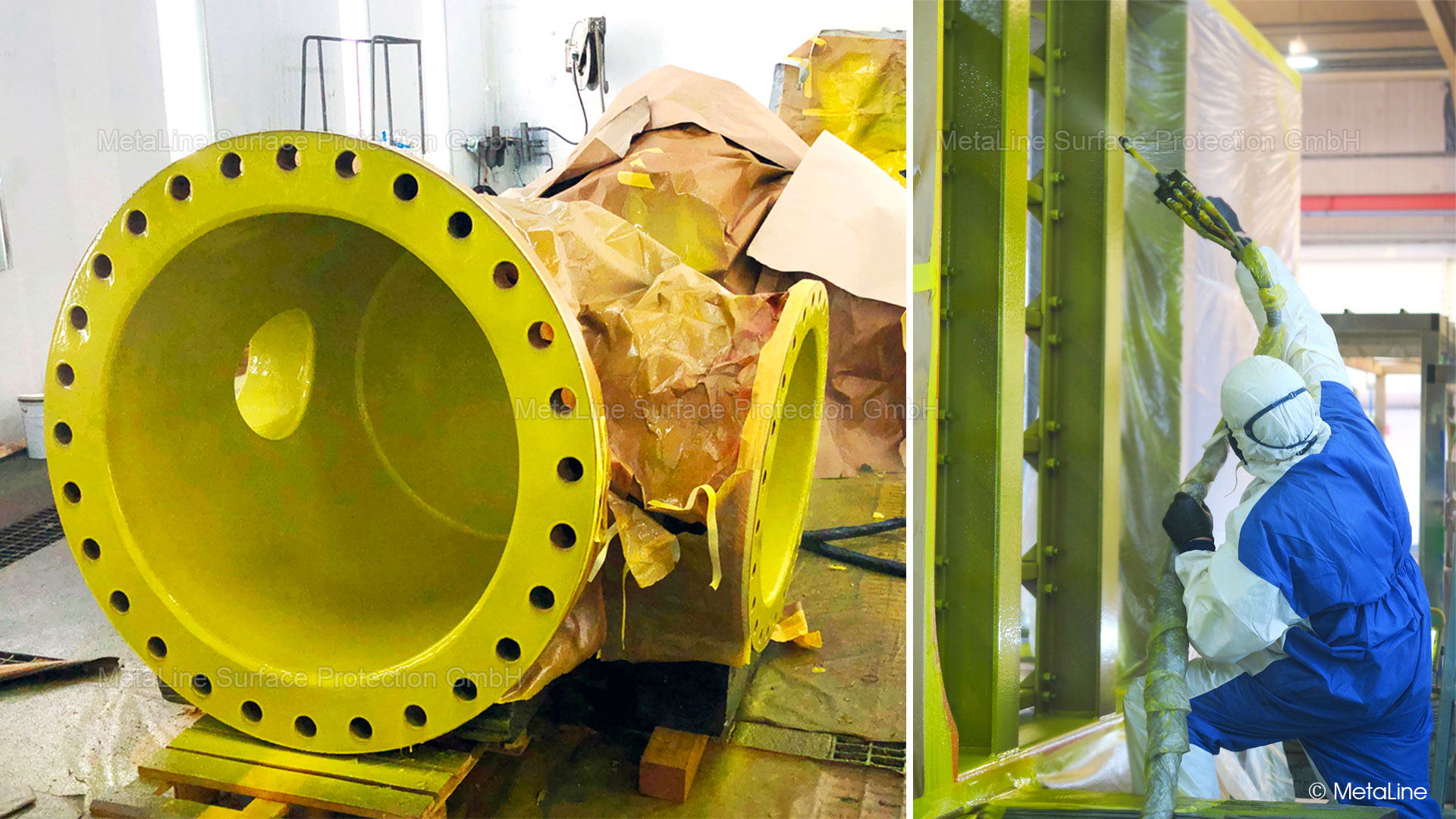

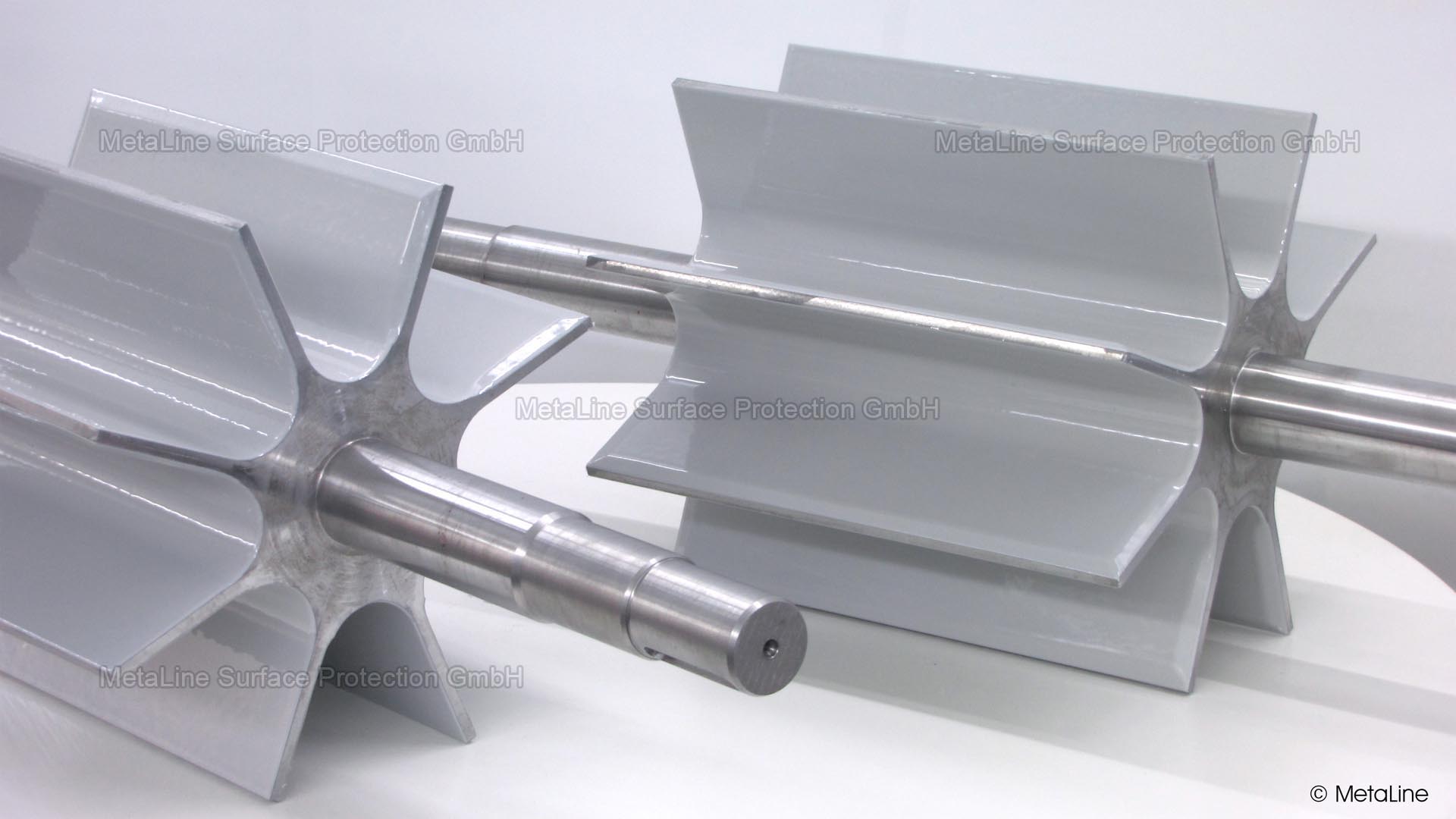

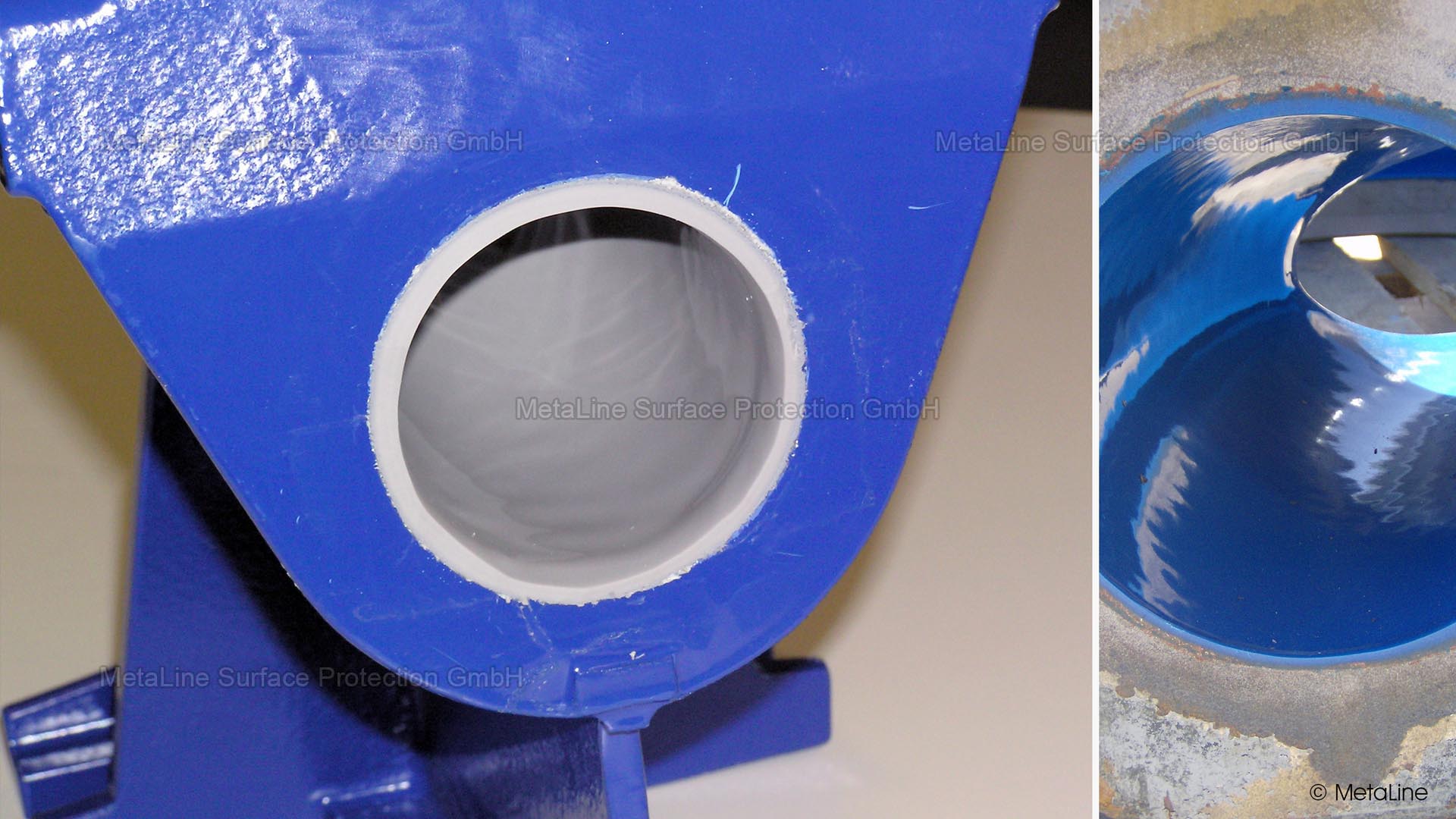

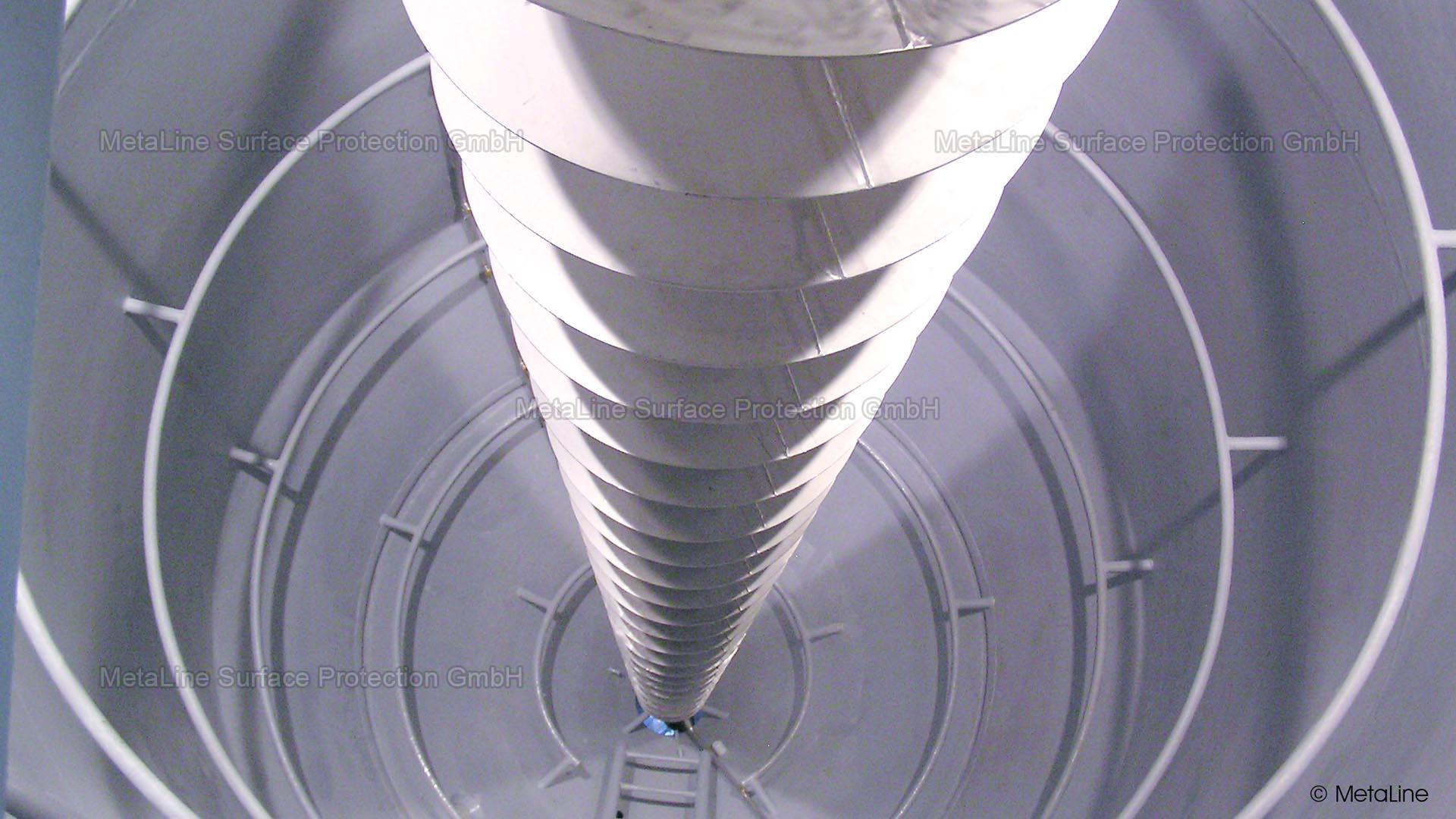

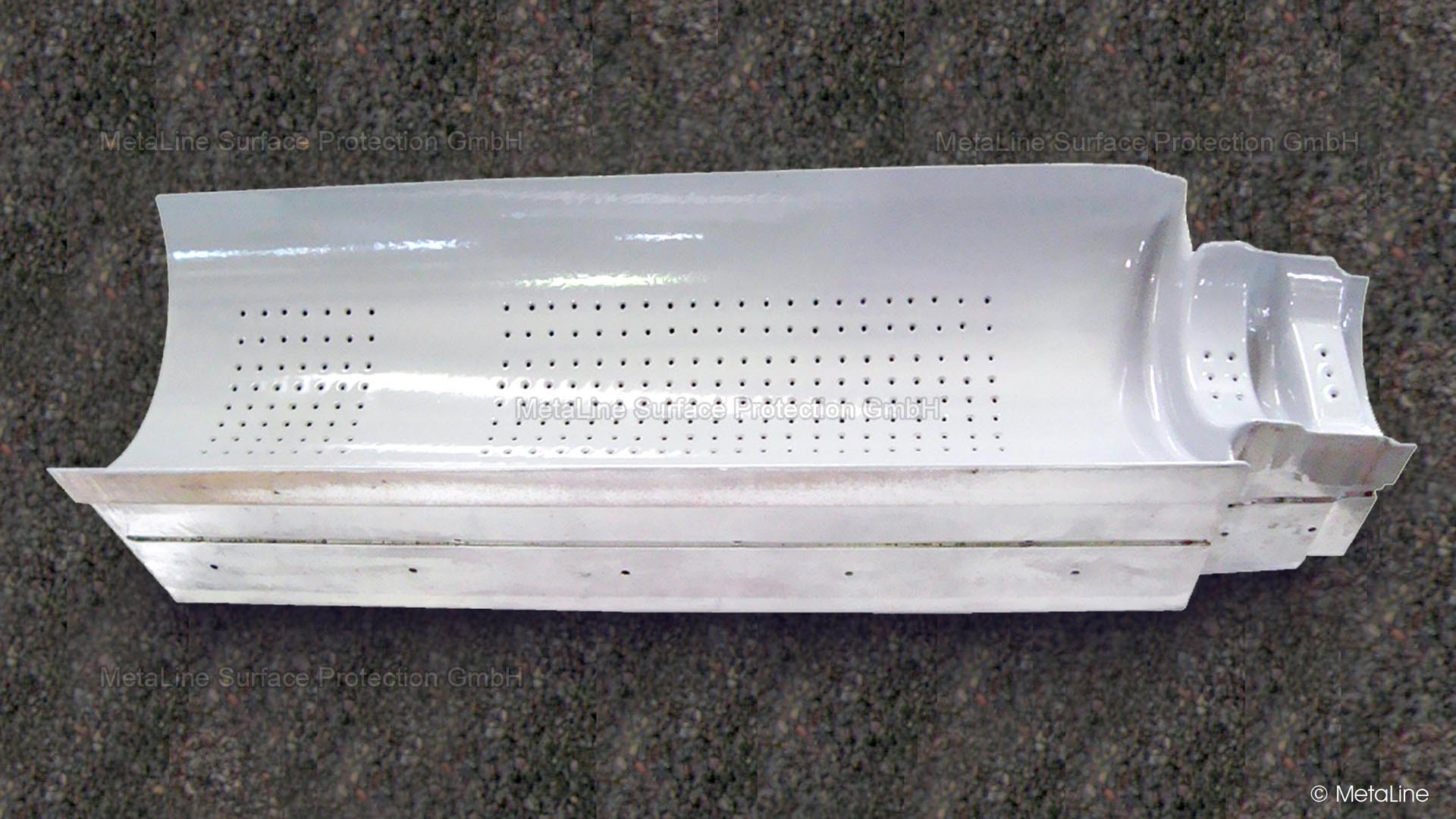

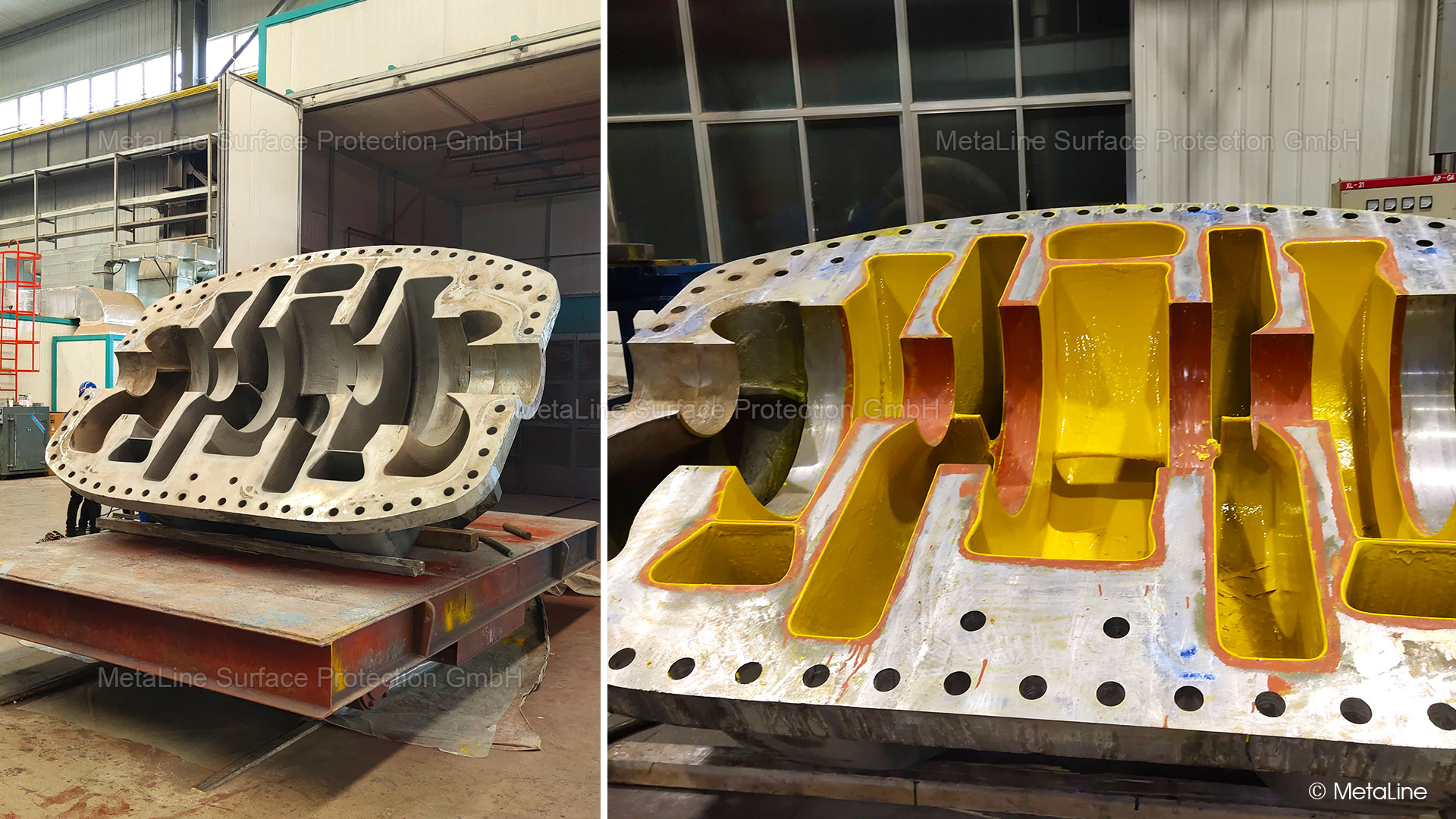

Adhesion protection - to avoid sticking problems Objectives Duroplastic MetaLine technology which can be retrofitted and cold-processed closes the gap between anti-stick protection and durability. Area impulses (loading, start of mixing, etc.) cause slight undulations of the elastic coating. This results in breaking loose of consolidated, static layers or simplifies their removal. Under difficult conditions this impulse behavior can be reinforced by a material combination consisting of MetaLine 760/795. This provokes even softer depth characteristics, i.e. stronger undulations. MetaLine coatings are not suitable, however, to build up non-stick characteristics towards sticky and dough-like smooth masses. Technical solutions in detail MetaLine Serie 795 - combines low static friction (my(0) = 0.15) with an extreme dynamic wear resistance. Elastic surface characteristics cause loosening of hard, brittle materials. One could say, indeed a long-term technology.